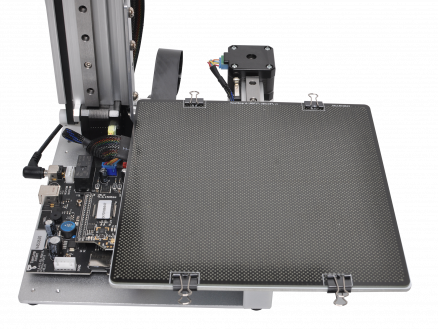

You could add filters in the Filters pane. You could create separate reports or comparative charts. Jason Wu: The machine is made with aluminum extrusion, sheet metal, and some relative simple CNC parts.Suppose you want your report readers to be able to look at overall sales metrics, but also highlight performance for individual district managers and different time frames. So there is no upfront tooling cost for this product. The whole machine is also highly modular, X,Y, Z axis modules are almost identical. The minimalist design and simplicity also allow easier and faster manufacturing of the products.

Therefore we can make the price more affordable with a relatively short lead time. What market are you targeting this machine for with these features? Hardware componets of the Cetus 3D printerįabbaloo: For such an inexpensive 3D printer, there are some interesting capabilities, like the ability to print layers as small as 0.05mm and a fairly large build volume of 180 x 180 x 180mm. Jason Wu: We are positioning this machine as a prosumer 3D printer with an entry-level price. Cetus is almost a plug and play device, first-time 3D printer users just need to fasten a few screws before it is ready to print. The machine is calibrated in factory so there is no need for the user to do so.

#CETUS3D SLICER SOFTWARE#

We provide straightforward software with optimized printing parameters so a beginner does not need to know all the printing parameters before getting started.įor advanced users, Cetus also provides freedom for tinkering. The software can change print temperature, so users could experiment with different materials. We will support GCODE in the near future, so the Cetus could be used with other slicers on the market. The printer’s extrusion body is able to accept standard T-nuts so user could easily modify it. An extra 5V output is on the extruder head, so an electronic add-on is also possible.

#CETUS3D SLICER UPGRADE#

We are also providing upgrades: In the kickstarter campaign, backers could choose to upgrade to a taller version with a build volume of 180x300x180mm.

#CETUS3D SLICER SERIES#

CETUS3D CALIBRATION SERIESĪ series of upgrades are also planned and will be release in the future. How does the machine maintain printing accuracy with far fewer rods and gantries used in other, more expensive machines? In one sentence, Cetus is targeting the general desktop 3D printing market covering from beginner to enthusiast.įabbaloo: The machine design seems to be very lightweight due to fewer parts. Jason Wu: The printer use high quality linear rails on all 3 axes our baseline is to use HIWIN or better rails.

#CETUS3D SLICER FULL#

The body is full metal and therefore very rigid. This results in excellent print accuracy and makes the printer very quiet as well. The Cetus desktop 3D printer comes with three different nozzle sizesįabbaloo: I’ve not seen an inexpensive machine with the ability to change nozzle sizes (the Cetus 3D offers 0.2, 0.4 and 0.6mm nozzles). What are these able to do for the operator? What benefits do they offer? Jason Wu: The different nozzles will provide much more freedom for operators to get better results for different purposes. If you need highly detailed prints, the 0.2mm nozzle could give double the resolution of the 0.4mm nozzle. You can go to our Kickstarter campaign to see the print samples. On the other hand, if you need something to be printed faster especially bigger prints, the 0.6mm nozzle will come in handy. The 0.6mm nozzle is also excellent for printing flexible materials such TPU/TPE and composite materials such as wood composite or metal composite materials.

What is the difference and why are two versions offered? Multiple materials may be 3D printed on the Cetus 3D printerįabbaloo: I’m told there are two versions of the Cetus 3D, one being the extended version.

0 kommentar(er)

0 kommentar(er)